CH. 7 Talent cultivation

126

Working hours are automatically counted by punch cards

at the Company HQ, and for ongoing projects, working

hours should be reported by the project site via the online

safety, health, and environmental management system on a

monthly basis for the duration of the construction. The safety,

health, and environmental management unit will export and

integrate workers safety statistics from the system as data for

the Company's annual working hour. Since Jan. 18, 2007 to

Nov. 30, 2015, CTCI HQ has received a certification record for

operating for 33,891,274 hours (we can apply for 38,4000,000

hours without work-related injuries the next time) without

work-related injuries from the Occupational Safety and

Health Administration, Ministry of Labor, demonstrating CTCI's

commitment and effort toward worker's safety. This record

comes from several material procedures. First of all, the

safety, health and environmental indicators for needs and the

risk management policy are considered, then the operations

of the system at the time will be utilized toward making

appropriate management targets on a yearly basis, and we

also routinely measure statistics related to workplace injuries.

To lower the damage and risk after the occurrence of

an accident, the Company has established a standardized

procedure to respond to accidents. When an accident occurs,

it will be assessed according to its severity, and each level will

form investigation teams and complete investigations within

a given timeframe. According to results of the investigation,

stringent regulations and rectification measures will be carried

out to prevent similar incidents from occurring again. Practical

rectification measures include implementing safety and health

educational training and enhancing workers' safety checkups

etc. Should a severe accident occur, internal departments

and local authorities need to be notified within a specified

timeframe, and the Company and the project personnel will

form a "joint investigation team" to investigate the problem.

And fill out a "problem investigation report rectification and

prevention measures report" according to results, in order

to truly carry out improvement and prevention measures in

practice. Based on results from investigations, we will conduct

a new round of risk and hazards assessment, and to learn

from the accident and to prevent future occurrence through

training.

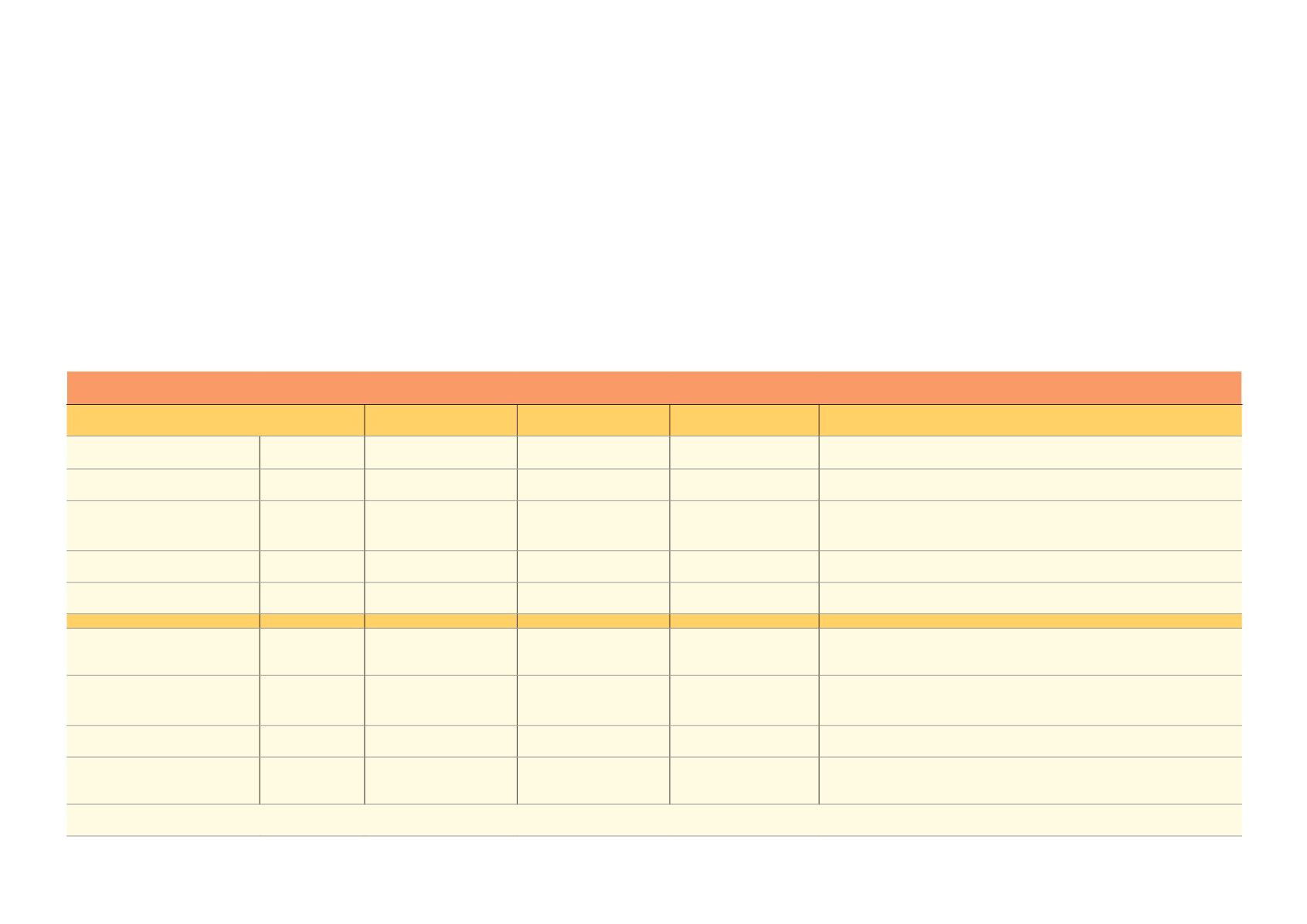

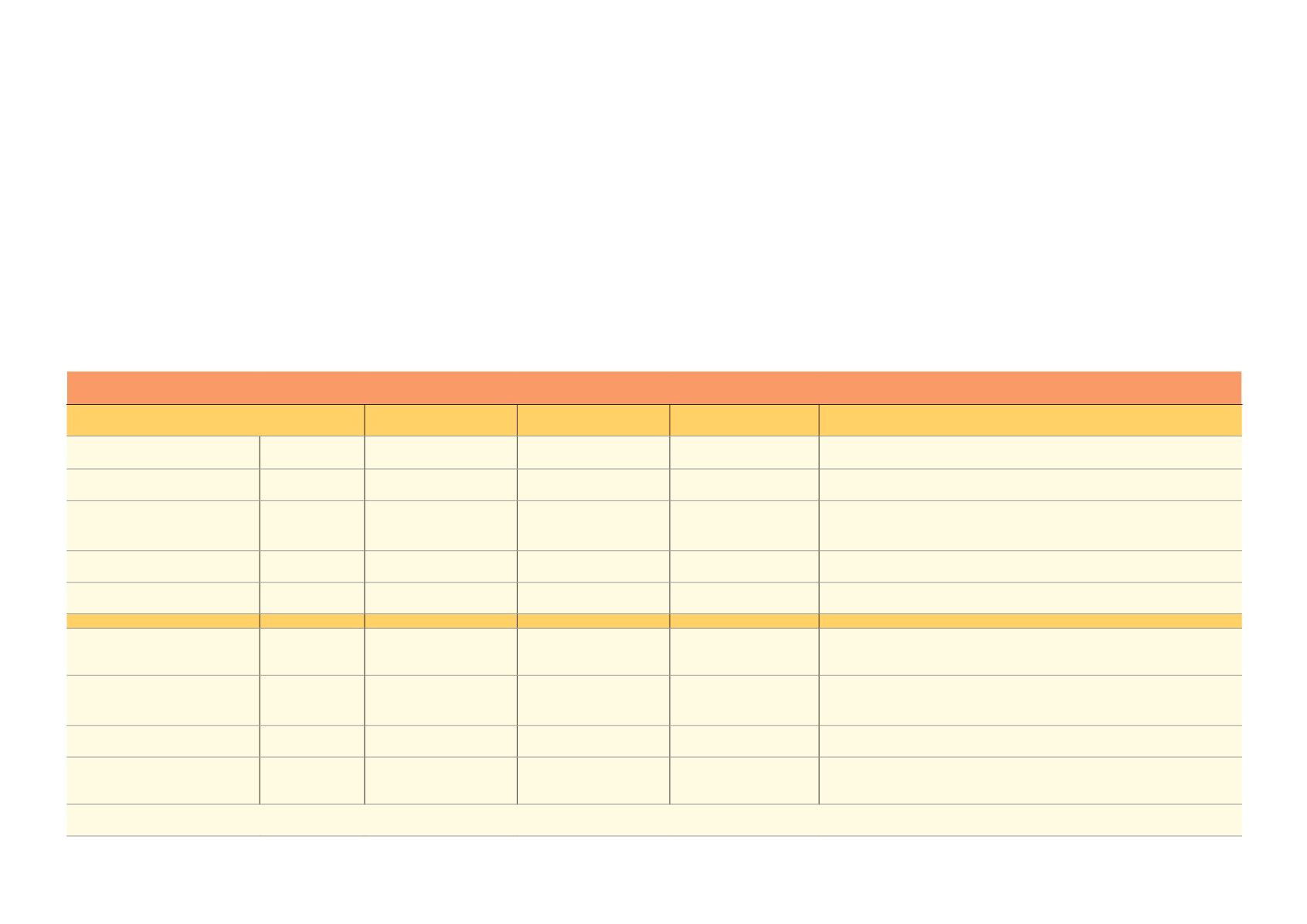

Various work-related injuries in last 3 years

Item

2013

2014

2015

Calculations

Rate of absence

CTCI

1457.27

1549.67

1971.72

Days of absence X 200,000/total working days per year

Total Recordable Case Rate

CTCI

0.03

0.07

0.10

Number of Recordable Cases x 200,000/ Total Hours Worked

Occupational Illness

Frequency Rate

CTCI

0

0

0

Occupational Illness x 200,000/Total Hours WorkedInjury Severity

RateLost Time & Restrict Days x 200,000/Total Hours Worked

Rate of days lost

CTCI

0.11

0

0.35

Total working days lost x 200,000/total numbers of working hour

Numbers of Fatality

CTCI

0

0

0

Rate of work-related injuries Contractors

0.06

0.08

0.12

Incidents of occupational hazards x 200,000/total numbers of

working hour

Rate of occupational hazards Contractors

0

0

0

Occupational illness x 200,000/total numbers of working hour

Rate of days lost

Contractors

0.26

0.14

0.22

Total working days lost x 200,000/total numbers of working hour

Numbers of deaths

Contractors

1

0

3

1 falling from heights incident in 2013. 2 falling from heights

incidents and 1 falling in 2015.

Note: male to female ratio in work-related injuries in 2015 was 14:1, and injured parties were all staff from contractors.