CH. 5 Environmental Protection

88

5.3.2

Usage of Raw Materials

In terms of choice of building materials, CTCI considers

durability, maintainability, VOCs, hazardous substances,

radiation, and life cycle. For instance, we have adopted

comprehensive use of PVDF coating in coated steel roofs

and walls to lower maintenance requirement for coastal plant

structures. To effectively minimize the leakage of VOCs, we

use low-emission valves in our designs, upgrading from 1,000

ppm emission valves to 100 ppm, thus lowering impact on

the staff and environment during the operation of a plant. For

green building designs, we largely use non-solvent paint and

other low-effusion green materials. For dry walls, we have

comprehensively adopted asbestos-free materials. In the

electrical engineering planning for the construction buildings,

we added PVC-coating in the metallic system-connecting

rod within the reinforced concrete to prevent corrosion, as

well as to prevent environmental pollution and to enhance

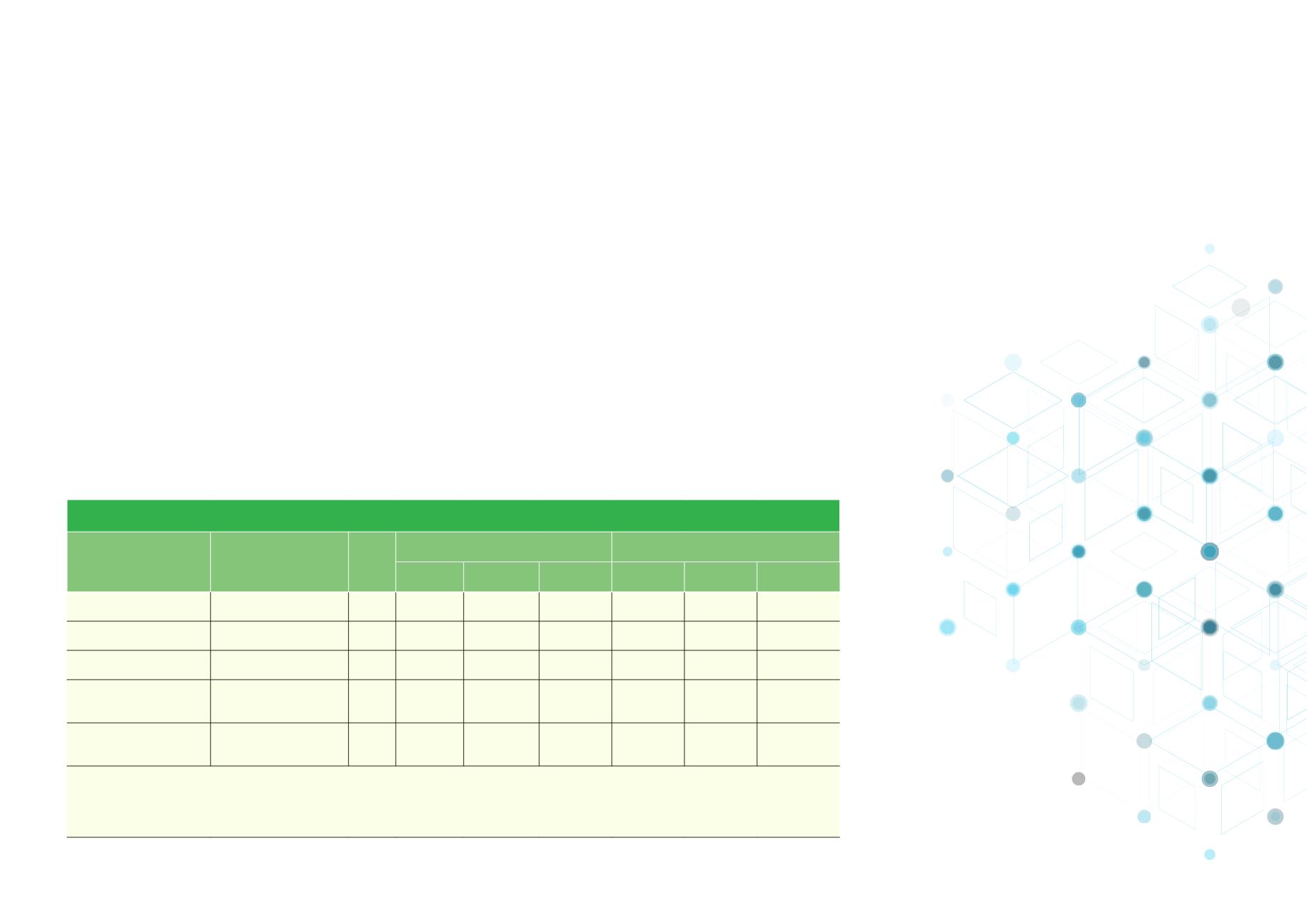

Usage of raw materials

Region

Raw material

Unit

Annual performance

Goal

2013

2014

2015

2015 Achieved

2016

Headquarters building

Paper

kg

107,958

98,644

65,810

103,301

O

82,227

Construction sites

Paper (Note 1)

kg

9,930

9,887

687,437

-

- 348,662

Construction sites

Steel pipe (Note 2)

tons

12,329

9,173

16,499

-

- 3,960,330

Construction sites

Recycled cement

(cinder) (Note 3)

tons

5,594

14,460

5,451

-

-

-

Construction sites

Recycled cement (slag

powder) (Note 3)

tons

5,594

14,460

6,290

-

-

-

Note 1: Only domestic data were available up to 2014. Data since 2015 include domestic and overseas amounts, hence the significant increase.

Note 2: Including Taiwan, Asia-Pacific, and Middle-East regions; Mainland China has been included since 2014.

Note 3: Accounting for 10% to 15% of all cement used.

Note 4: The goals were to remain below the average of the previous two years.

its durability and life cycle. We also opted to use low-fume

and nontoxic cables and wires that are heat-resistant so

that not only can we reach expected power supply during

emergencies, we can also prevent toxic materials from

spreading during the fire and causing further complications.

As to prevent the humidity and chemicals corrosion facilities

such as equipment, structure and cables in the petrochemical

plants, we always had to keep the quality of paint in mind

during construction. To minimize the paint’s effects on human

bodies, we selected paint that has met the environmental

standards during design phase, in order to decrease the risks

of affecting the operational staff from paint additives.With the

newly-introduced life cycle cost analysis software (EEA), we

calculate energy consumption and life cycle cost. In addition

to analyses of economic factors including loans, cash flow,

and recovery period, we include internal and external energy

consumption and costs including those involved in operation,

maintenance, and decommissioning, extending life cycle

analysis to over 20 years.

In the management of the consumption of office supplies,

we have continued to emphasize minimizing unnecessary

printing. When printing is necessary, we print double-sided to

minimize paper consumption. In addition, since 2012, we have

begun to install card identification devices on all multi-function

printers. Employees are required to obtain printed material

using their employee ID card. Double-sided printing setting

is adopted on all computers, minimizing paper consumption

while reminding employees to conserve paper.