CH. 5 Environmental Protection

80

In the process of executing a project, applying green

engineering to constructions while continuing to develop new

technologies is the greatest technical challenge for the sustainable

growth of an construction company. Supported by technologies,

CTCI uses the latest eco-friendly processes in all its current plant

construction contracts. Compared with the previous generation of

processes, environmental impact has been significantly decreased,

which shows that we have contributed to both economic

growth and environmental protection. With strong engineering

development capabilities and technological background, we

are able to more quickly accumulate technical experience when

involved in international constructions and collaborating with

international construction companies. CTCI not only continue to

develop green technologies but has also applied its technologies

in many plant construction projects and has achieved outstanding

results.

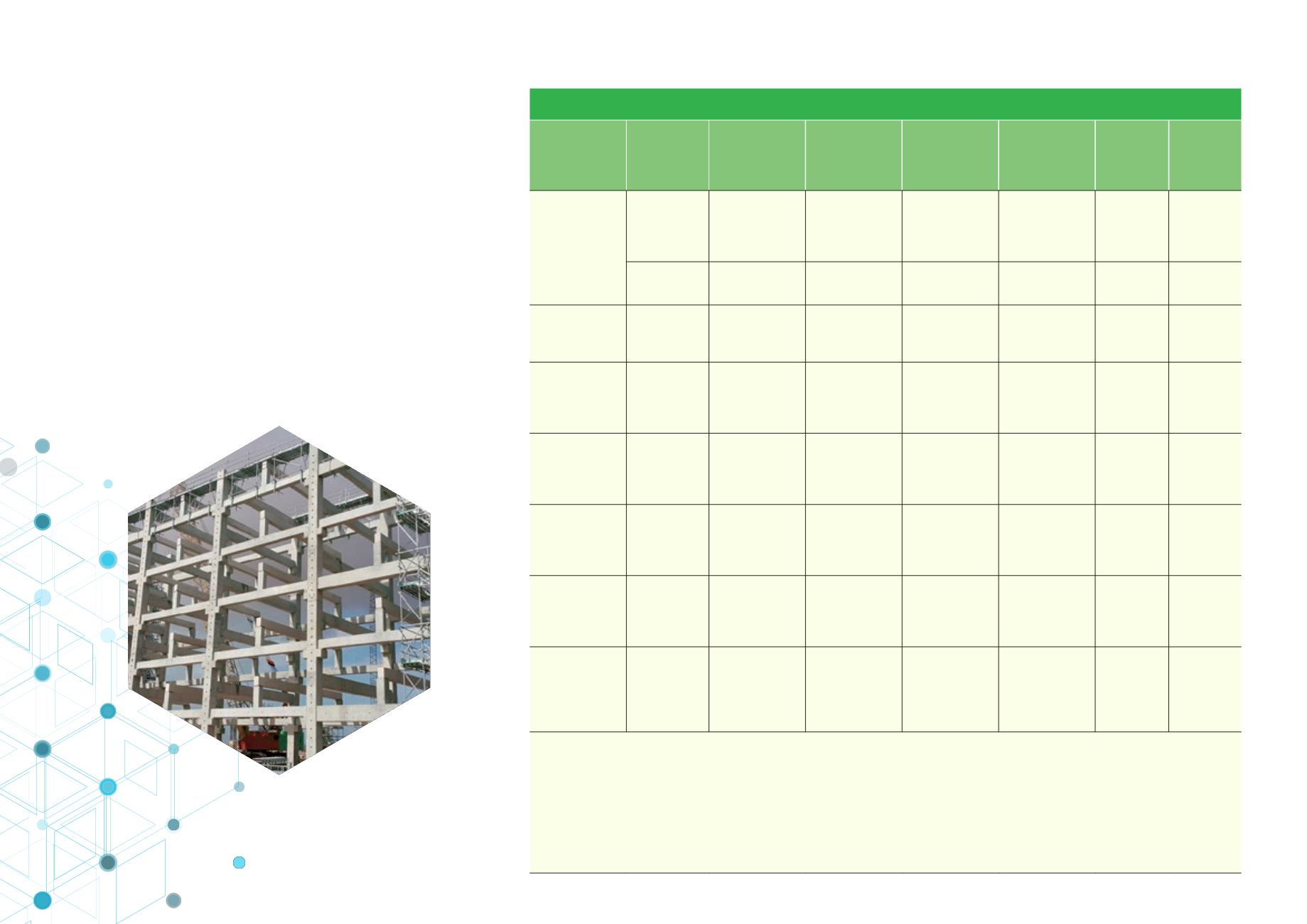

Performance and Effectiveness of Indicative Green Engineering in 2015

Green

Engineering

Technology

Type of

Energy

Saved

RTO project

(Note 1)

Condensate

refinery

project

MMA/

PMMA

project

(Note 2)

RFCC

project

(Note 3)

DHDS

project

(Note 4)

LCD

glass

project

(Note 5)

Process

energy-

saving/ heat

recovery

Thermal

energy

(million

kcal/year)

53,944

85,128

918,740

1,351,527

-

-

Electricity (

kWh/year)

-

-

-

2,656

-

Water saving

Water

(10,000

tons/year)

-

-

6.2

-

9.51

8.41

Application

of high-

efficiency

motors

Electricity

(kWh/year)

-

-

1,130.02

190.99

656.53

-

Application

of inverter

driving

devices

Electricity

(kWh/year)

-

3,323.54

6,9236.42

-

-

-

Application

of high-

efficiency

transformers

Electricity

(kWh/year)

-

-

-

-

77.53

228.64

Application

of low-

emission

valves

VOCs (ton/

year)

-

530.9

238.1

2,235.1

393.5

-

Application

of Value

Engineering

(VE) in plot

plan

CO

2

e (ton)

-

-

717.4

665.7

13.7

-

Note 1: RTO = Regenerative Thermal Oxidizer

Note 2: MMA/PMMA = Methyl methacrylate / Poly Methyl methacrylate

Note 3: RFCC = Residual Fluid Catalytic Cracker

Note 4: DHDS = Diesel Hydrodesulfurization

Note 5: LCD = Liquid Crystal Display

Note 6: Annual electricity saved is calculated based on 24-hour operation for 365 days per year. According to information published by

the Bureau of Energy, Ministry of Economic Affairs in 2014, the CO

2

e per kWh of electricity is 0.521 kg. Annual electricity saved in outdoor

lighting is calculated based on 12-hour operation for 365 days per year; Calculation for indoor lighting is 24-hour operation for 365 days

per year.

Precast concrete installation