CH. 4 Professional Engineering Service

61

4.3.2

Enhance internal and external quality evaluation

● Enhancement of preparations for project quality auditing

To further enhance the quality and effectiveness of quality

auditing, we have reassessed and enhanced the checklist

of key items in the project auditing in 2015, and established

fundamental verifications according to the Company's

first and second step procedure and the most updated

legal regulations. We also require the project assurance

managers to add on audit items according to the specific

type of the project, contractual requirements, and the

project progress during the time of the verification, to serve

as basis for our internal project verification. Furthermore,

the Quality Management Department requires departmental

meetings prior to holding a project auditing, in order to

ensure that the project assurance manager understands

the key of auditing.

● Enhance stringency of reporting system, and to track and

monitor improvements.

Due to the decrease in quality from suppliers all over the

world and the news on dishonest vendors and products

from time and again, we have stringently required our

auditors to report on nonconformity found during 2015

internal auditing. As such, we may ensure stringent quality

control to our suppliers and partner companies and CTCI's

engineering quality can better match customer needs, legal

compliance, and that the quality of our projects match our

contractual requirements. Through electronic management

system, we will track the revision progress of each defect,

and require vendors, partner firms, and our colleagues to

implement revisions in practice.

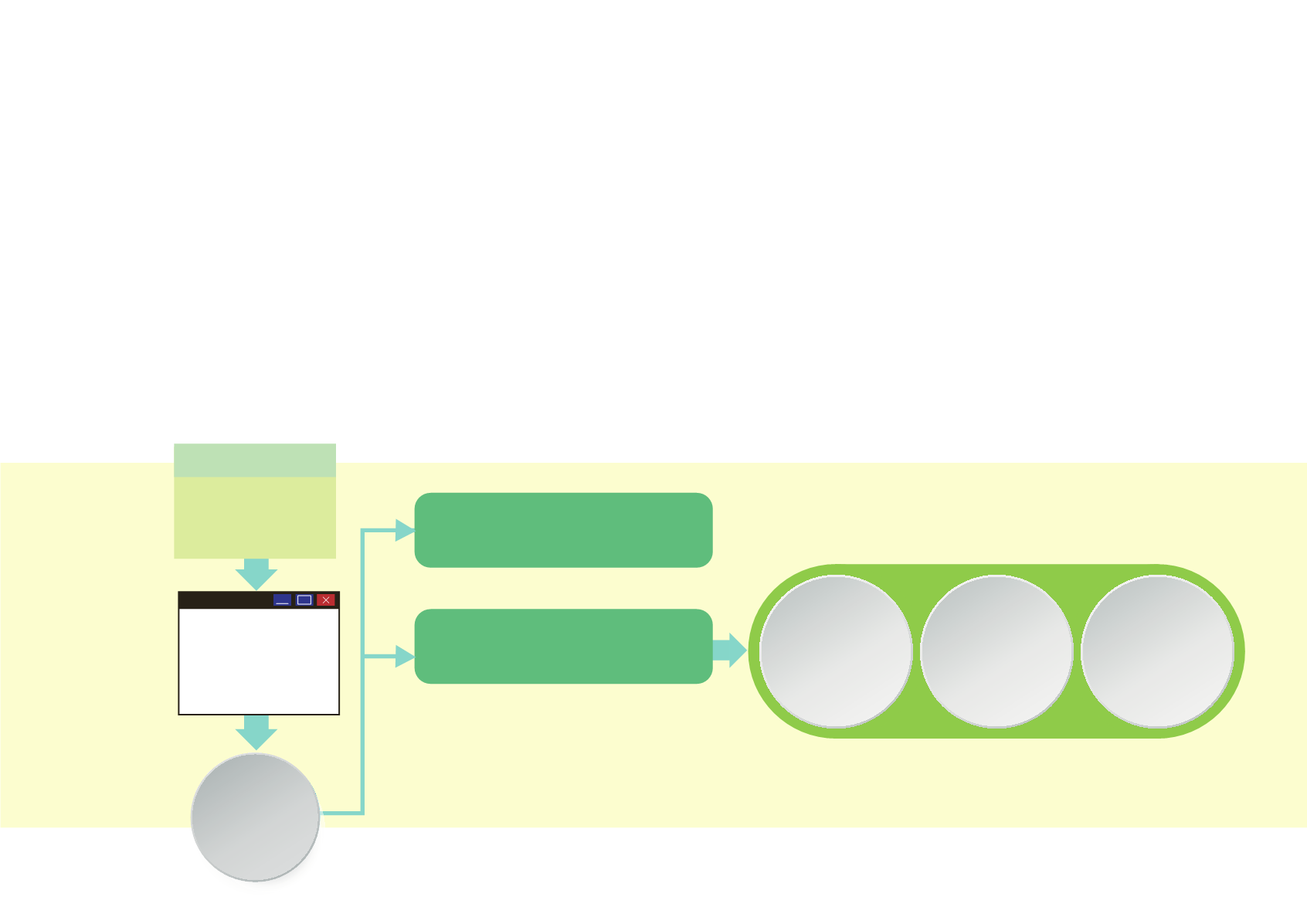

underlying

causes Analysis

Related

Implementation

Procedures

Revise

Related

Implementation

Procedures

Review

L & L

Announcement/

Advocacy,

Education and

Training

Improvement

Measures

Immediate Improvement

Defects Correction

Lessons Learned

Preventive Measure

Quality Defect finding

• Defect Data Collect

• Responsible Unit

Identification

● Strengthen statistical analysis of defects and to revise and

improve the major causes of defects through practice

To strengthen the precision of the quality and evaluation

of the quality auditing report, we require auditors to add

categories of defects and explanations for its underlying

causes to the report, and to integrate defects found in each

project auditing for comprehensive statistical, systematic

root causal analysis on a monthly basis. And appropriate

improvement measures will be drawn with project

engineering/procurement/construction/commissioning

management unit, and the responsible unit of the project

will be in charge of the improvements. At the same time,

'Lessons & Learned' will be written and distributed, or

relevant procedures and control mechanisms may be

revised as needed to ensure that the quality of each project

task complies with regulations, contracts, and procedural

requirements.