CH. 4 Professional Engineering Service

57

Innovation is one of CTCI's business principles, and we

have always strived toward the introduction and R&D of new

technologies. To implement our innovative developments in

practice, CTCI has established the Innovation R&D Center

to be in charge of processes, tools, and methods of R&D

or project improvements. The Director of Innovation is our

executive vice president, and he supervises over three

groups: 'New Product Development,' “Process Innovation,“

and “New Operation Technology Development”. In order to

enhance our efficiency in project executions, the Innovation

R&D Center continues to focus on the R&D in information

integration between multiple disciplines, expansion for the

breadth and depth of engineering technologies, as well as

design automation.

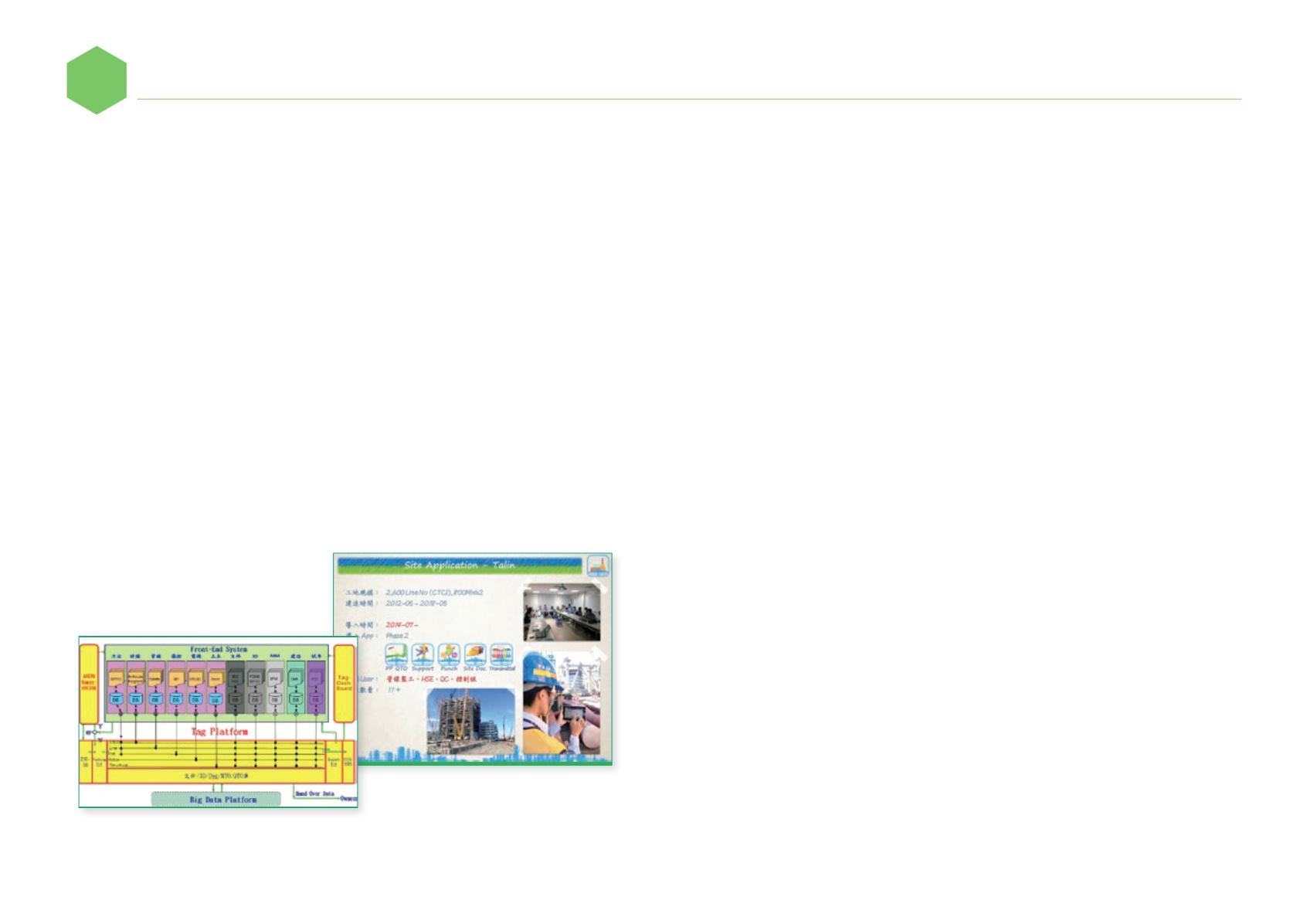

CTCI has commenced various R&D projects since

2015, and has devoted over NT 81,217 thousand into these

research projects. To create competitive differentiation and

advantage, development of iEPC

*1

is undergoing to shift the

manner of EPC operation from “batch processing” to “multi-

issued processing”, so that each design modification can be

supervised in time, allowing all

operations to be fully integrated

and effectively managed. The

engineering-object-oriented

Tag Platform

*2

, acting as the

foundation of iEPC, improves

project control capability and

increases the efficiency of

project execution by organizing

associated documents, 3D

models, material take-off, material

requisition, installation quantities

and layout across stages of

engineering, procurement,

construction and commission,

into a chain of project engineering information and agile

data. Also, job site efficiency is enhanced with continuous

promotion of mobile devices and applications utilized at key

job sites, so that construction information is more accessible

via portable e-form. Regarding ISO

*3

layout control, we

implemented QR code

*4

to ensure each installation is done in

correct layout, and on top of that, Intergraph SPC

*5

is applied

to construction management, allowing construction planning

simulation, availability of layout drawings and materials, as

well as actual installation progress, to be displayed in 4D

visualization, so that construction schedule is managed more

effectively.

With the enhancement of technology expertise, we have

accomplished the research FMEA/CA

*6

, the basic design

of applying thin film application to zero-liquid discharge

system, the design of stud bolts welded to the steel column

embedded in RC piers, truss supported conical roof tank

structure design, pulsation and piping vibration analysis for

reciprocating compressor, and cathodic protection application

for offshore structure and facility. Moreover, we have revised

our internal design guidelines and existing engineering

software according to the updated codes/standards and the

information we collected form engineering practices from

domestic or abroad.

In terms of design automation, we have continued to

refined pump seal plan selection system, developed more

applications for Revit BIM 3D

*7

, and completed the automated

control room layout design, the automatic modeling of typical

piping around units equipment, and CAD program for power

system, all of which greatly enhanced the quality, speed, and

accuracy of EPC project executions.

Innovation and development

4.2